Unknown

Design of Tea Land flavored teabags export boxes

Tarh Heram Company has been proud of its nearly 20 years of experience as an advertising consultant to reputable brands such as TNT International Post, SGS International firm, Aria SGS, LG company, Kan exhaust hood, Sama Naghale company, Marlino company, Linx company, Wana Hasti Alborz company, etc. and has provided a wide range of services to its customers over the years.

The basic principles of quality, speed and customer satisfaction have always been a key element of Tarh Heram Advertising Company's activities and this has led to continued customer service and communication for many years.

One of the projects that started in 1989 is the design, printing and production of export boxes of Tea-Land flavored tea bags, which we describe below.

"Principle One: Being Specific".

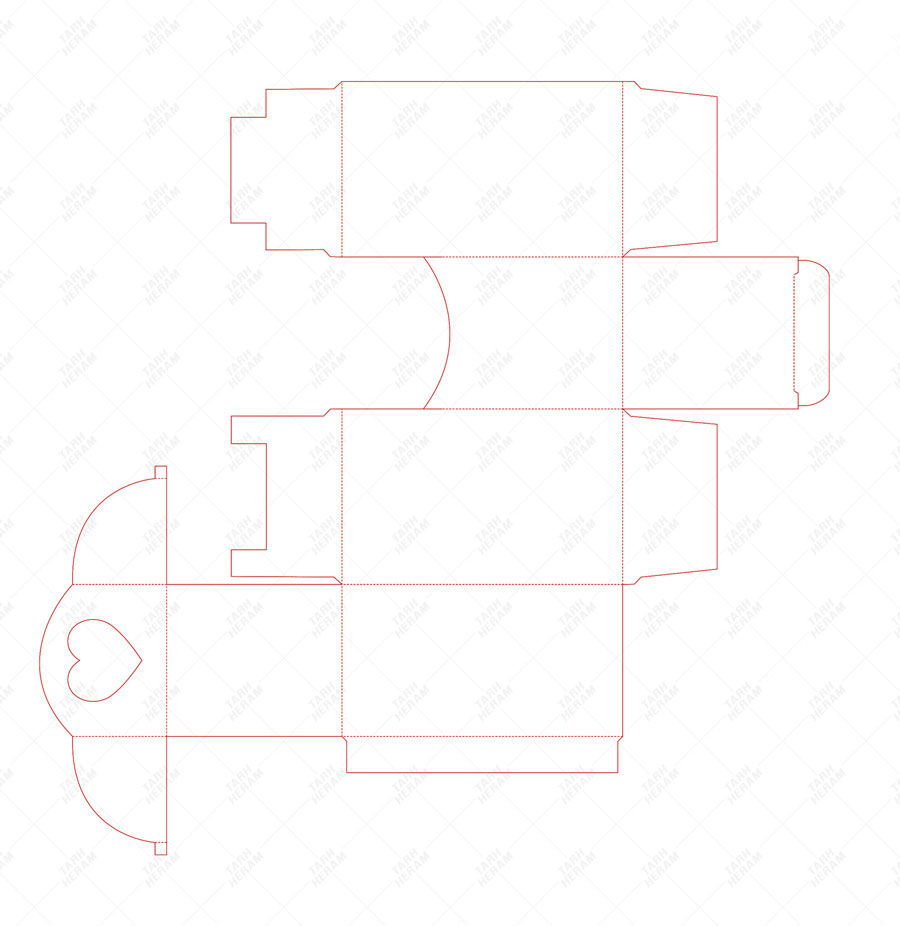

Format design:

Before beginning of the graphic design of Tea Land export boxes, it was necessary to design an appropriate format, which was beautiful, creative, specific and most importantly executable, easy-to-produce, efficient, after designing several different formats and presenting them to the customer, the customer's design was announced to Tarh Heram design company.

Design of Tea Land flavored teabags export boxes

Tea-Land manufactures 6 types of tea bags with different flavors, the most important for brands that produce a product with different flavors is the harmony of the layout and color of the products, in the way that fully coordinating the design together, they should be easy to distinguish.

Thinkers and designers of the Tarh Heram design studio company prepared and tested different colors for nearly 3 months and tested different colors spectra and after accurate examination of different layouts, submitted the selected designs to the customer for approval. In this part, Tea-Land company announced its design and submitted its amendments and proposals to the Tarh Heram company.

Making maquette:

After completing the customer's corrections, replication is performed several times after printing to maximize the effect of the design and to eliminate possible design and format flaws, and to check for complete alignment of the various dimensions of the boxes. Replicas are sent to the customer and final corrections are made by the customer, after the customer's final approval the designs are ready for printing.

( Selected design )

Printing process: "accuracy, key of success"

Once the design is approved, it is time to prepare the designs for printing, at which point the designers of the Tarh Heram company will double-check all the design elements for more coordination such as: Percentage of color scheme, font size, font color, reading out texts to avoid misspellings, image quality, icons, standard marks, etc. These items are checked over and over again so that the slightest drawback is not left in the final design.

Formatting:

At this point, depending on the size of the work, and the size of the boxes, formatting experts put layouts together on one page and prepare them for printing.

In the case of Tea Land boxes, due to its proper size and mold format, it was possible for the designers to put both of the two boxes in one printed form, according to the customer's desire, the boxes were divided into double three forms depending on the amount of consumption, and were ready for printing.

Choosing a suitable paper for printing tea box

Due to the essential role of cardboard in the beauty and strength of the box, choosing the right cardboard for printing is very important and sensitive, cardboard genus, cardboard thickness, opaque and glossy, etc. are important issues to consider in choosing cardboard.

A variety of cardboard samples were examined for Tea Land export boxes, such as the inderboard cardboard 250g, inderboard 300g and Inderboard 350g, which were finally approved by the customer and after making maquettes with Inderboard 300g to print tea boxes. Due to the high circulation of the boxes, Tarh Heram company purchased the required cardboard supplies from first-hand suppliers of paper and cardboard and purchased the required cardboard at the most appropriate price possible.

Printing:

Due to the extensive cooperation of Tarh Heram company over the past 20 years with dozens of reputable and quality printing offices and recognizing the strengths and weaknesses of these printing offices, the company has explored the different capabilities of printing offices to perform better printing of Tea Land exported tea boxes.

( Printed boxes )

One of the important things to determine a good printing office is the ability to print four colors simultaneously on 300 grams of inderboard cardboard, as conventional printing machines cannot print on 300 grams of inderboard cardboard, and only Roland and CD printing machines have this capability.

After agreement of the Tarh Heram company with the appropriate printing office, the printing project was completed with the presence of the Tarh Heram printing supervisor. During printing, the samples were repeatedly matched to the original sample to ensure that all printed forms were in perfect harmony with quality and color.

Opaque lac coating:

Opaque lacquered coating was used to stabilize the color and prevent scratches on the boxes in other steps of the work, as well as a more localized post-printing UV coating for more parade, which had a greater effect on making the box more beautiful.

Localized UV

Localized UV is a glossy coating to attract more attention and create beautiful visual effects that are positioned locally on the printed opaque surface, this technique was used to make Tea-Land export tea boxes more beautiful, and parts of it, such as the gold line around the box, were used on the logos and on the teapot design on the box.

Mold making

Due to the specificity of the mold design, the mold file was sent to the molding workshop to be produced by advanced machines, precision and laser molding. After preparing the mold to ensure accurate mold performance, it was sampled using a die cut machine and several replicas were made from the final form of Tea Land export boxes.

Molding

After complete printing and drying of UV, the printed forms were sent to the molding workshop for molding and box forming, and started with the presence of the print supervisor and the quality control manager of the sampling project and after removing the prototypes from the molding machine, maquette were reproduced from samples to eliminate any possible defect in the mold. After the maquette was confirmed, all printed forms were molded and prepared and the box was adhered.

Box adhered

Usually the boxes are packed with advanced, very fast and accurate adhesive machines, but in the case of Tea Land boxes, due to the specific form of the boxes, this was not possible, as a result, these boxes were manufactured in a hand-made box-making workshop using double-sided adhesive, the use of double-sided adhesive causes much cleaner work in addition to much higher strength, because of the non-use of liquid adhesives.

Delivery to customer:

In order to deliver the ready boxes to Tea Land company, according to the flavor of each box, the boxes were divided and arranged in larger cartons with special order that would be easier to maintain and use in future and was sent to the customer in the Tea Land factory site.